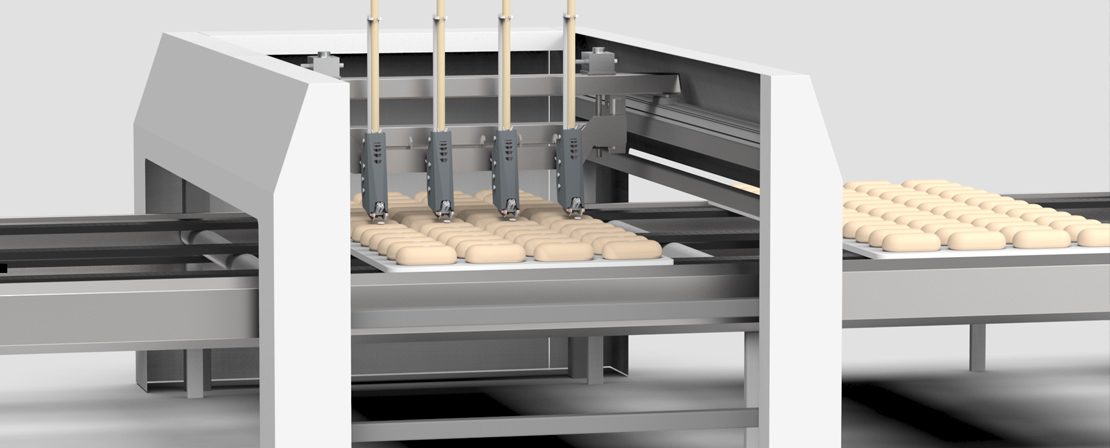

Applicator Machine – Automatic Application of Wafer Labels on the Bakery Line

Gives the bakeries the possibility to cut labor costs and hence improve profitability. It can be installed into existing or new bakery lines with extremely low cost and need for space.

We will be launching our developed applicator machine for edible labels soon. This machine brings you:

- Significant cost savings for manual application

- Increase efficiency and speed up production

- Installation on any existing and new bakery production line

The edible label applicator is adaptable to any bakery production line, where it can replace the manual application of edible labels to your bakery product, or for installation in fully automated plants, so they can start using edible labels.

The amount of production capacity depends on the number of units and the type of solution. The capacity of a single unit is 3000 – 5000 pcs/hour. So if someone needs high production capacity, they can choose a combination of e.g., 6 units, and the capacity will be 18000 – 30000 pcs/hour.

Labels for filling the applicator are supplied lined up in a tube-shaped foil containing 1400 units, which are then inserted into the applicator tray. The applicator in its full state contains 1700 labels. If required, the number of pieces in the tray can be increased.

Current concepts:

- A variant of a single solution above the belt conveyor for applying to the dough before proofing

- Variant multi-unit on continual line for high volume capacity bakeries

- Variant one or more units on the movable axe above the row of products on the belt conveyor

If you are interested, please make an appointment with us at IBA or email us at info@bread.cz.